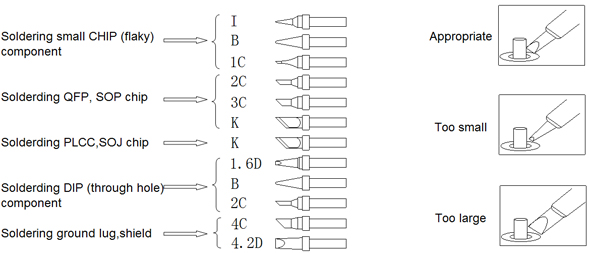

Choices of solder tips

1.Choose a solder tip for maximum contact area, which can produce the most effective heat transfer, so that the operator can soldering high quality solder points quickly.

2.Choose a good path to transfer heat to the solder tip, the shorter length can get more precise control of the temp of the soldering station, but weld dense circuit board,you need to use a longer or a certain angle soldering iron.

Use of solder tips

| *Tips temperature |

The high temp will weaken the iron tip. So, as far as possible choose the low temp. This soldering station back temp quickly, even if the use of a lower temp can be sufficiently welded to the temp, and can protectsensitive components.

|

| *Clear | Should regularly clean sponge to clean iron tip. after solder tip residual flux derivative health oxide and carbide damage iron head, caused by poor soldering, or make iron head the thermal conductivity of hypothyroidism. continuously for a long time using a soldering iron, aweekly disassemble the iron tip oxide removal to prevent Iron head damage and affect the soldering temp. |

| *When not using | Not using a soldering iron, you can not let the soldering iron for a long time at a high temp state, will iron tip flux into oxide, resulting in thethermal conductivity of the iron tip function is greatly diminished. |

| *After using | After using, you should clean up tip coated with a new layer of tin toprevent oxidation of the iron tip does not stick tin. |

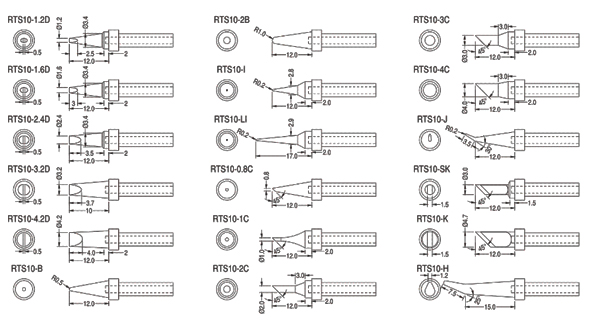

Replace solder tips specifications

Suitable for YMK RT-S0100、YMK RT-S0150 Series Soldering Stations:

View Big Image

View Big Image